IMPACTORS: MAKING AN IMPACT

The Impactor, our single-shot pneumatic “hammer,” has earned an excellent reputation among foundries around the world. The value of the Impactor lies in its robustness, power and longevity.

The combination of extremely long “time between rebuilds” and the affordability and availability of replacement parts translates into a low cost of ownership that continues to win the approval of customers—especially those who have experience with other units.

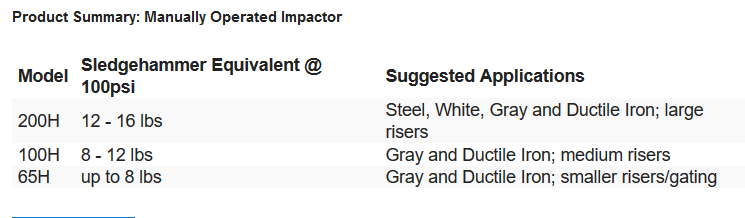

There are three Impactor models: 65H, 100H and 200H. They are designed to replace sledgehammers in removing risers made with break-off style cores. All operate best at 80~150psi and are equipped with our patented cushion cylinder for excellent protection against dry-firing. Impactors are operator-friendly (ergonomic grips, shock cushioning), and are built to withstand the rigors of continuous foundry use.

Available Options

Air Quality System (highly recommended): Protects your investment and helps to assure peak performance.

Handlebar-mounted Hoist Control: Allows the operator to control a customer-supplied hoist (electric or pneumatic) without removing his hand from the grip.

Pneumatic Intensifiers are also available for boosting supply pressure up to 2X, providing up to 150psi to the Impactor for increased power.

The Impactor is also available in the form of a manipulator-mounted attachment, either alone or in combination with other tools. Our patented Combination Grapple/Impactor attachment is the most productive riser removal and casting handling package available.

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Codelco cuts 2025 copper forecast after El Teniente mine collapse

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Barrick’s Reko Diq in line for $410M ADB backing

Abcourt readies Sleeping Giant mill to pour first gold since 2014

Nevada army depot to serve as base for first US strategic minerals stockpile

SQM boosts lithium supply plans as prices flick higher

Viridis unveils 200Mt initial reserve for Brazil rare earth project

Tailings could meet much of US critical mineral demand – study

Kyrgyzstan kicks off underground gold mining at Kumtor

Kyrgyzstan kicks off underground gold mining at Kumtor

KoBold Metals granted lithium exploration rights in Congo

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Kyrgyzstan kicks off underground gold mining at Kumtor

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Silver price touches $39 as market weighs rate cut outlook