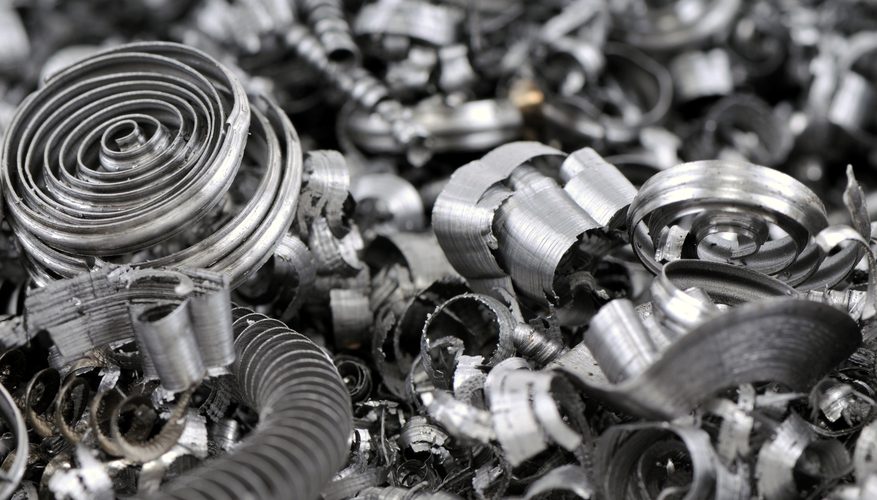

Stainless steel scrap deviates from nickel price rally

"There is a de-coupling of the stainless steel and nickel market," one processor said at the sidelines of the BIR conference in Budapest, Hungary last week.

The three-month nickel contract traded on the London Metal Exchange (LME) rallied in July after the Indonesian government first discussed bringing forward its planned nickel ore ban by two years from 2022. The policy was confirmed in September and Indonesia will stop exporting low-grade nickel ore from 1 January 2020.

Following the announcement of the ban, the LME three-month nickel price rocketed to a five-year high at $18,475/t on 2 September, up 52pc from $12,120/t on 2 July. Prices have since corrected downwards to $16,885/t on 25 October but continued to hover at around four-year highs.

Prices for 304 stainless steel scrap solids did move up throughout July and August in response to the nickel rise, with the Argus weekly 304 scrap solids cif Rotterdam price rising from €980-1,050/t on 4 July to €1,100-1,150/t on 12 September.

But the pace of the increase lagged the meteoric nickel increase. The average Argus weekly price assessment of 304 stainless steel scrap solid over the 4 July-5 September period was €1,076.25/t ($1193.29/t), compared to an average LME nickel price of $15,000/t over the same time.

Since mid-September, the 304 price has actually fallen back to its early-July level. The Argus stainless scrap solids 304 (18-8) cif Rotterdam price was assessed at €950-1,000/t on 24 October, equivalent to 47.9-50.5¢/lb.

The 304 stainless steel series typically contains 8pc nickel and 18pc chrome. The price formula of stainless steel scrap consists of nickel payables — calculated based on a discount to the LME nickel contract — and chrome prices. The nickel payables are negotiated between the stainless steel mills and blenders every month in Europe.

In Europe, the average nickel payables for 304 stainless steel scrap solid for delivery to mills in October settled at 63pc (equivalent to 37pc discounts to LME nickel contract). This is 5-10 percentage points lower than the average payables of 68-73pc in May-September.

For November, payables were concluded as low as 55pc in some deals.

Nickel payables are normally around 95pc but the discounts have widened significantly since mid-2018 as mills negotiated successfully for lower payables. Mills have argued for cheaper feedstock prices because of poor demand for stainless steel products as a result of an influx of cheap imports from China and Indonesia.

"Historically, payables are just below 95pc of LME nickel, at 95pc it's already bad," said one nickel trader.

When the discount was at 30-32pc in the third quarter, one processor commented that "the discount has never been this big", yet the payables continued to breach new lows, which has hurt processors' profit margins.

"The problem is [the payables] decreasing so fast in such a short period of time. If it's stable, we can keep our margin," a second processor said.

Stainless steel mills calls for lower feedstock prices

Stainless steel mills such as Finland-based producer Outokumpu has openly called for lower feedstock prices in order to compete with cheap imports from Asia.

Unlike Chinese and Indonesian stainless steelmakers, European producers rely mostly on the 304 series stainless steel scrap, followed by ferro-nickel as the main feedstock. European mills then use refined nickel to ensure the nickel content is met in different alloys.

According to market participants, stainless steel scrap accounts for up to 80pc of European stainless steelmakers' feedstock.

Integrated Chinese-owned stainless steelmaker Tsingshan Holding Group set up a 3mn t/year mill in Indonesia and production started in 2017. Tsingshan Indonesia also operates its NPI and chrome mining, which enables the steelmaker to benefit from low-cost production.

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Codelco cuts 2025 copper forecast after El Teniente mine collapse

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Barrick’s Reko Diq in line for $410M ADB backing

Abcourt readies Sleeping Giant mill to pour first gold since 2014

Nevada army depot to serve as base for first US strategic minerals stockpile

SQM boosts lithium supply plans as prices flick higher

Viridis unveils 200Mt initial reserve for Brazil rare earth project

Tailings could meet much of US critical mineral demand – study

Kyrgyzstan kicks off underground gold mining at Kumtor

Kyrgyzstan kicks off underground gold mining at Kumtor

KoBold Metals granted lithium exploration rights in Congo

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Kyrgyzstan kicks off underground gold mining at Kumtor

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Silver price touches $39 as market weighs rate cut outlook