Primetals Technologies receives FAC for modernized DC twin electric arc furnace at Baosteel in Shanghai, China

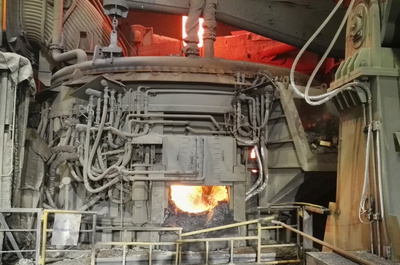

The project involved redesigning both the upper and lower vessels and installing new anodes with increased durability. Improved power efficiency reduces production costs and raw materials can be used more flexibly. It is therefore now possible to operate the electric arc furnace with a hot metal content of up to 90 percent.

Baoshan Iron & Steel Co Ltd. is part of the newly formed China Baowu Steel Group Corp Ltd, the second largest steel producer in the world, with a production capacity of 70 million tons. Baosteel produces high-quality products for both the Chinese domestic and the world markets. The twin electric arc furnace at the Shanghai plant has a tapping weight of 150 metric tons and is part of a production line on which billets and long products are manufactured for use as structural steels.

150-metric-ton twin electric arc furnace at Baosteel in Shanghai, China.

Under the modernization project Primetals Technologies was responsible for engineering, manufacturing and supplying essential components. The upper vessels with their water-cooled wall panels were completely redesigned, and the lower sections each were equipped with a new, air-cooled FIN anode. Overall, electric power efficiency levels and thus productivity was improved. New burner systems also were installed. It is now possible to operate the twin electric arc furnace with a hot metal content of up to 90 percent. Primetals Technologies was likewise responsible for monitoring the installation and commissioning work.

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Codelco cuts 2025 copper forecast after El Teniente mine collapse

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Abcourt readies Sleeping Giant mill to pour first gold since 2014

Barrick’s Reko Diq in line for $410M ADB backing

Nevada army depot to serve as base for first US strategic minerals stockpile

Tailings could meet much of US critical mineral demand – study

Viridis unveils 200Mt initial reserve for Brazil rare earth project

SQM boosts lithium supply plans as prices flick higher

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Silver price touches $39 as market weighs rate cut outlook

First Quantum drops plan to sell stakes in Zambia copper mines

Ivanhoe advances Kamoa dewatering plan, plans forecasts

Texas factory gives Chinese copper firm an edge in tariff war

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Silver price touches $39 as market weighs rate cut outlook

First Quantum drops plan to sell stakes in Zambia copper mines

Ivanhoe advances Kamoa dewatering plan, plans forecasts