Arcelor Mittal Galati contracts Danieli for continuous slab caster (CC4) revamp

Arcelor Mittal Galaty has placed its trust in the technological packages and expertise in revamping projects of Danieli, for the quality upgrade of its 9.7-meter radius slab caster installed in Galati in 1978.

The installation of a new longer mould, an optimized secondary cooling on a new segment 0, and completely new Level 1 and Level 2 systems, supplied by Danieli Automation, will improve product quality by reducing slab defects like sliver, flakes and spider cracks for coils and plates.

The upgrade will be performed during a 21 day shutdown in September 2017.

In-classroom and on-site training will also be provided operator's personnel.

After the revamping the plant will produce 220-250-mm x 700-1900-mm slabs in low-carbon, peritectic, medium-carbon, micro alloyed, high-carbon and silicon steel grades.

Referring to ArcelorMittal Group, Danieli Davy Distington technologies for slab casters have been installed at Industeel and Sidmar in Belgium, Meizieres, Dunquerke and Fos-sur-Mer in France, Tubarão and Acesita in Brazil.

The Technological Packages included in Galati project are:

- Q-INMO hydraulic oscillator software;

- Q-LEVEL+ mould level control system with automated mould powder feeding;

- Q-MAP real time mould thermal monitoring system;

- Q-WIDTH in-line mould width and narrow face taper adjustment;

- Q-MIX tundish mix prediction system;

- Q-CUT slab cutting process optimization;

- Q-ART in-line slab quality assessment.

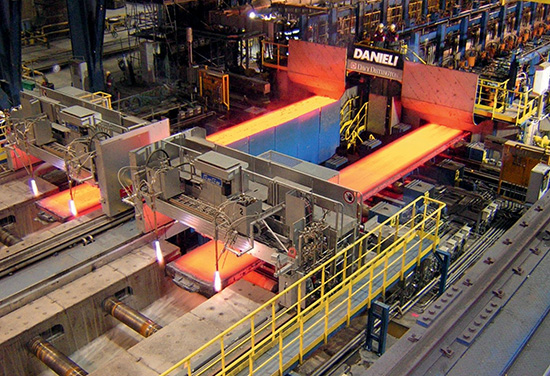

Continuous Slab Caster at ArcelorMittal Fos-Sur-Mer (France), after Danieli revamp.

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Codelco cuts 2025 copper forecast after El Teniente mine collapse

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Barrick’s Reko Diq in line for $410M ADB backing

Abcourt readies Sleeping Giant mill to pour first gold since 2014

Nevada army depot to serve as base for first US strategic minerals stockpile

SQM boosts lithium supply plans as prices flick higher

Viridis unveils 200Mt initial reserve for Brazil rare earth project

Tailings could meet much of US critical mineral demand – study

Kyrgyzstan kicks off underground gold mining at Kumtor

Kyrgyzstan kicks off underground gold mining at Kumtor

KoBold Metals granted lithium exploration rights in Congo

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Kyrgyzstan kicks off underground gold mining at Kumtor

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Silver price touches $39 as market weighs rate cut outlook