Mintal Group China at a glance

Mintal Group is the largest manufacturer of high carbon ferrochrome in China, and largest commercial stainless steel manufacturing base in northern China. Its major clients include Baosteel, Tisco, Jisco, Zhangjiagang Pohang, and Guangzhou Lianzhong. Mintal Group was ranked top 3 in the “Top 100 Fastest Growing Companies of China” award and “Best Iron and Steel Companies of China”.

Currently, Mintal Group has introduced world advanced ferrochrome production technology from Outotec, Finland. The technology was awarded “Clean Technology Prize” by Finland, and “Best Available Technology” by EU. Mintal Group plans to invest about 3,000,000,000 RMB to set new ferrochrome plant in Jiuyuan Industrial Park. The new plant is very energy efficient and environmental friendly. Its unit power consumption level is 20% lower than industry average. Its emission is 60% lower than industry average. Mintal Group aims at becoming one of the top players in the industry.

Mintal Group Strategic goal is " Keep a global vision; build the top Chromium Circulation Base in China and dopt the best available technology and provide the best products to the customers."

- In 2002, set the experimental unit of ERP in Mintal Group. It is been widely applied in 2008, we build up the Accounting Computerization (U8) and Office Automation (OA), Enterprise Intranet and management system.

- In 2005, Mintal Group invested the special steel industry which has great market prospect and development potential.

- In September 2007, Mintal Group took over Wuhai New Century Alloy Company.

- In 2007, Mintal Group changed the production model from Multiple Products to Advantages Products Specialization.

- In 2007, Mintal Group and its subsidiary company realized the financial integration management.

- In August 2008, Mintal Group realized the Capital Stock Diversification, China Minmetals Corporation and Goldman Sachs became our shareholders. The Sales income increased to 2.3 billion, comparing to the 660 million in 2007.

- In 2008, Mintal Group established International Trade Department and Beijing Office in Beijing, and Tianjin Office in Tianjin Port.

- In August 2010, Mintal Group achieved ISO9001 Quality Management System Certification.

- In 2010, Mintal Group established and continuously improving the manufacturing management and appraisal system to ensure all the work would function in well planned and highly effective way; and all the work would finish with plan, arrangement, fulfillment and appraisal.

- In June 2011, Mintal Group and Outotec Oyj, signed contract for supply of chromite pelletizing and ferrochrome smelter. This is the first such kind technology upgrade project in China. Outotec technology will improve product quality and reduce energy consumption.

Mintal Group introduce pellets belt roasting oxidation technology from Outotec. The annual output is 700,000 tons SBSTM chrome pellet. SBSTM chrome pellet is mixture of chrome concentrate with small amount of coke fines, through milling, filtrating, pelletizing and sintering, etc.

(1)Symmetrical small size, it is helpful to improve the burden permeability and balance airflow.

(2)High intensity, it will not been crushed easily during transportation, storage and loading.

(3)High metallurgy property and bulk intensity, it will help to increase production output and decrease energy consume.

(4)High reducibility, it can improve the usage of furnace chemical energy. The Cr2O3 content of SBSTM chrome pellet is higher than 42%, the physical property fulfill the YB/T 005~006-91 standard.

The size of SBSTM chrome pellet is 6-12mm. The qualified size is more than 98%, only less than 1% lower 6mm size.

High Carbon Ferrochrome – Base Material of Stainless Steel

High carbon ferrochrome is a carbon reduction product intermittently outgoing from the furnace. It is produced from ferrochrome minerals in the electric smelting furnace for continuous smelting by using the silica as flux and carbon as reducing agent.

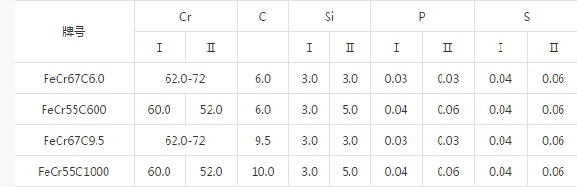

High Carbon Ferrochrome is the solid solution of chromium, ferrum and carbon, complex compound of chromium, ferrum and carbon. The essential component is (Cr、Fe)7C3, silver-white metal, brittle. The specific weight is 6.5-6.7g/cm3, bulk specific weight is 3.8-4.0t/m3. The melting point is 1550℃, electric conduction. High Carbon Ferrochrome fulfill GB/T5683-1996 standard.

- High carbon ferrochrome is lump shape, each weight ≤15kg, size less than 20×20mm, no more than 5% of the total weight. No sonims inside. The product will crush, package and deliver according to buyer’s requirement.

- High carbon ferrochrome is the Base Material of Stainless Steel.

- Chromium is the only element to determine the attribute of stainless steel. All stainless steel contains chromium.

- In 1954, Krivsky came up with reducing the partial pressure of CO by vacuum or mixed gas (argon-oxygen) refining to produce stainless steel.

- In 1965, German Witten Company developed VOD Method, using high carbon ferrochrome produce stainless steel.

- In 1968, American Jocelyn Company developed AOD Technology to produce stainless steel by using high carbon ferrochrome.

- From now on, high carbon ferrochrome became the base material to produce stainless steel.

- Mintal Group introduce 2×69MVA OPKTM preheating closed furnace from Outotec. It can preheat the raw material and recycle the gas, which is low carbon, energy saving, environment friendly. The annual output is 300,000 tons high carbon ferrochrome.

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Codelco cuts 2025 copper forecast after El Teniente mine collapse

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Barrick’s Reko Diq in line for $410M ADB backing

Abcourt readies Sleeping Giant mill to pour first gold since 2014

Nevada army depot to serve as base for first US strategic minerals stockpile

SQM boosts lithium supply plans as prices flick higher

Viridis unveils 200Mt initial reserve for Brazil rare earth project

Tailings could meet much of US critical mineral demand – study

Kyrgyzstan kicks off underground gold mining at Kumtor

Kyrgyzstan kicks off underground gold mining at Kumtor

KoBold Metals granted lithium exploration rights in Congo

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Kyrgyzstan kicks off underground gold mining at Kumtor

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Silver price touches $39 as market weighs rate cut outlook