Italian ring producer buys newly developed ring rolling machine from SMS group

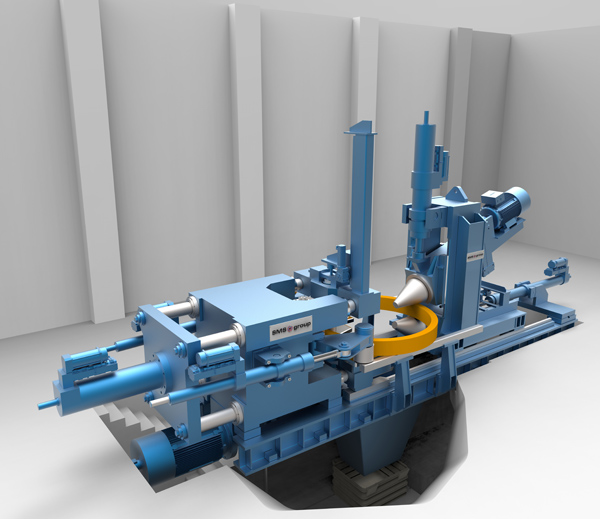

SMS group has developed a new ring rolling machine and already won the first customer for the new technology. The Italian ring producer, Forgia Rapida from Bologna, has placed an order with SMS group for the supply of an RAW 100/80-3000/480 ecompact® radial-axial ring rolling machine.

The RAW ecompact® for Forgia Rapida will replace a smaller ring rolling machine in operation at the Bologna works and will in future roll rings with diameters up to 3,000 millimeters and a maximum height of 480 millimeters. The radial rolling force will be 1,000 kN and the axial force up to 800 kN. SMS group will deliver and install the machine in summer 2016. Start of production is scheduled for September 2016. The short delivery times and speedy erection and commissioning are essential elements of the newly developed machine concept. Rings with standardized dimensions can be used for testing and verifying the performance parameters. As a matter of course, also rings from the current production stock can be used. This will ensure that the machine reaches its full performance capacity within a very short time.

“The cost-benefit ratio of this new development has really impressed us,” says Lorenzo Badini, owner of Forgia Rapida, commenting on the investment. “We are convinced that it will pay back shortly. ”

The investment costs for the RAW ecompact® are around 20 percent lower than for conventional ring rolling machines. Furthermore, the fact that the otherwise common central hydraulic system has been dispensed with means no associated machine and foundation pipework needs to be installed. This not only provides economic benefits, but also eliminates the risk of environmental pollution by oil leakage. The RAW ecompact® is mounted on a simpler foundation than conventional ring rolling machines, and additional installation space for a separate hydraulic power pack is not required. Operating costs are reduced as a result of not only the savings on energy but also due to the almost complete elimination of hydraulic oil. That means notable savings also on process media. Additionally, the noise level has been lowered significantly. “We no longer have a complex oil circuit, but just compact electric drives – and for that we need no more than two cables,” says Robert Düser, Manager Sales Ring and Wheel Rolling, SMS group. “This ring rolling machine is unique in the world.”

SMS group developed the new machine concept within a period of about eight months. The RAW ecompact® operates fully automatically based on CNC. The machine is supplied complete with the “CARWIN” (Computer Aided Rolling under Windows) control software and the “ROLLTECH Rings” technology software. CARWIN controls the rolling process. After the target data for the rings to be produced have been entered, the software will check all data for plausibility and, together with the CNC system of the ring rolling machine, it will provide for an automatic rolling process. The ROLLTECH software will simulate the ring rolling process in order to ensure rollability of the planned products and generate all required process parameters. After the operating personnel has entered the final ring geometry and the material data, ROLLTECH Rings will calculate the necessary machine settings on the basis of stored process models. The two programs allow ring manufacturers to reliably reproduce any product that has ever been produced in the past.

SMS group manufactures the new machines in a variety of sizes. The largest one has been designed to produce rings with a maximum outside diameter of 3,600 millimeters with horizontal unloading. The RAW ecompact® for Forgia Rapida will produce, among others, rings for radial compressors, reciprocating piston compressors and gas turbines. The Italian manufacturer currently produces around 4,000 tons per year of forgings.

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Codelco cuts 2025 copper forecast after El Teniente mine collapse

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Barrick’s Reko Diq in line for $410M ADB backing

Abcourt readies Sleeping Giant mill to pour first gold since 2014

Nevada army depot to serve as base for first US strategic minerals stockpile

SQM boosts lithium supply plans as prices flick higher

Viridis unveils 200Mt initial reserve for Brazil rare earth project

Tailings could meet much of US critical mineral demand – study

Kyrgyzstan kicks off underground gold mining at Kumtor

Kyrgyzstan kicks off underground gold mining at Kumtor

KoBold Metals granted lithium exploration rights in Congo

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Kyrgyzstan kicks off underground gold mining at Kumtor

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Silver price touches $39 as market weighs rate cut outlook