Swiss steel Emmenbrücke has awarded MET/Con the order to supply a PQA® for quality management along the complete production chain

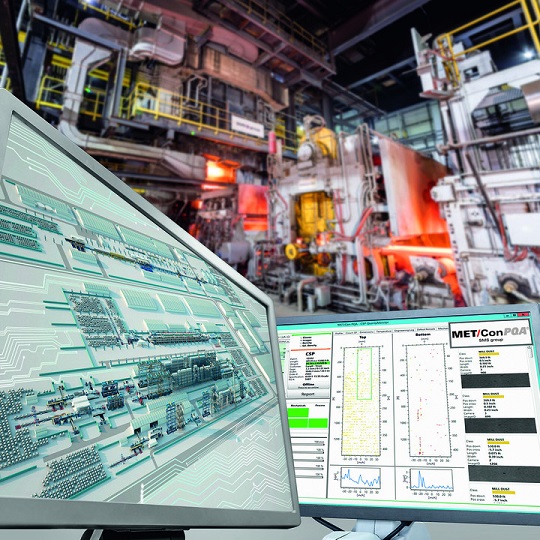

The new PQA® Product Quality Analyzer from MET/Con is going to be implemented at Emmenbrücke as a pilot for a group-wide Industry 4.0 initiative. With this quality management system, Swiss Steel aims to further enhance the quality level along the entire production chain, achieve more stability in the production process, further improve on-time delivery performance and optimize the company’s competetiveness in the long run.

MET/Con, a company of SMS group, was commissioned to supply an integrated IT solution operating on knowledge-based expert rules. Use will be made of an advanced software and database solution from Aachen-based QuinLogic, an SMS group company. Solutions based on this approach have been successfully implemented at selected flat steel producers with a great variety of downstream processes.

The PQA® system carries out online analyses of process, production and quality data from steelmaking, casting and rolling, right down to the drawing processes. The PQA® expert quality rules, which can be freely configured and fed with specific knowhow, take into account customer- and order-specific information in the quality assessment process and for the block-or-release decisions for the next downstream processing step.

The modular software consists of a LogicDesigner for flexible rule adaptation, a quality assessment module and web-based reporting. The centerpiece of the quality management system is the DataCorrelator software module, which covers latest features such as “Big Data” analyses and artificial intelligence (AI). Various intelligent mathematical evaluation methods, including pattern recognition options, identify and indicate correlations that can be directly used for process optimization.

With this project, Swiss Steel, Steeltec and MET/Con want to set a milestone showing how the performance, efficiency and quality level of the mill can be further improved by gaining total process and production transparency.

The PQA® quality management system from MET/Con is designed to enhance the quality level, stabilize the production process, improve on-time delivery performance and secure competitiveness.

Trump weighs using $2 billion in CHIPS Act funding for critical minerals

Codelco cuts 2025 copper forecast after El Teniente mine collapse

Electra converts debt, launches $30M raise to jumpstart stalled cobalt refinery

Barrick’s Reko Diq in line for $410M ADB backing

Abcourt readies Sleeping Giant mill to pour first gold since 2014

Nevada army depot to serve as base for first US strategic minerals stockpile

SQM boosts lithium supply plans as prices flick higher

Viridis unveils 200Mt initial reserve for Brazil rare earth project

Tailings could meet much of US critical mineral demand – study

Kyrgyzstan kicks off underground gold mining at Kumtor

Kyrgyzstan kicks off underground gold mining at Kumtor

KoBold Metals granted lithium exploration rights in Congo

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Kyrgyzstan kicks off underground gold mining at Kumtor

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility

China extends rare earth controls to imported material

Galan Lithium proceeds with $13M financing for Argentina project

Silver price touches $39 as market weighs rate cut outlook